Accessories

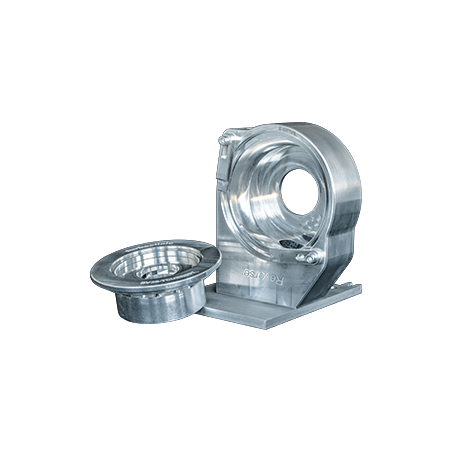

Universal Exhaust Housings - Reverse Turbo Exhaust Housing

- Fast fitting of different cores

- Developed for Reverse Turbos

- It doesn’t require an OEM exhaust housing

- Adaptors developed for the best simulation of the air flow